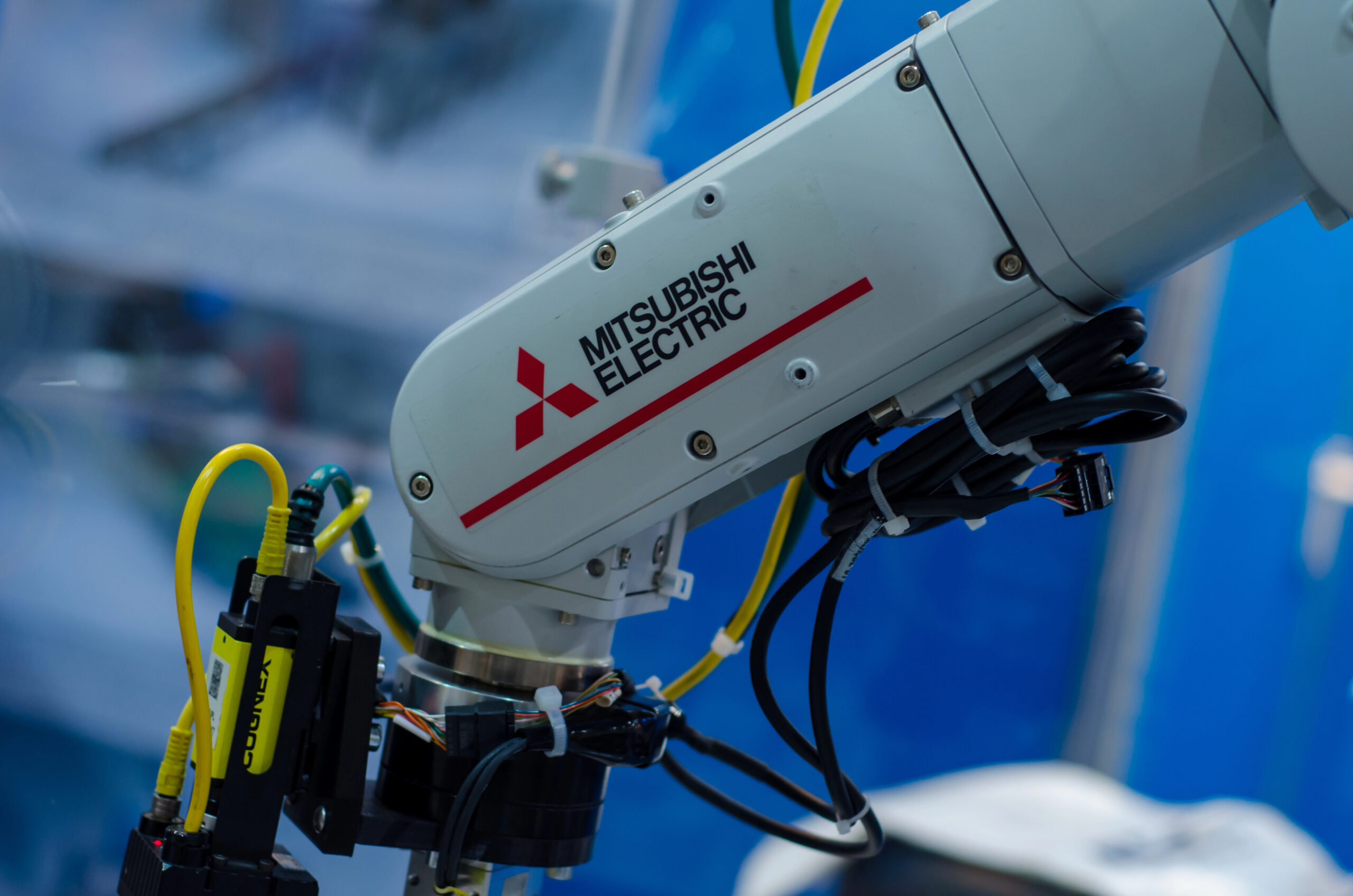

In today’s rapidly evolving industrial landscape, there is a significant shift towards automation, particularly in Asian manufacturing hubs. As this trend reshapes factory floors; it’s also driving impressive financial growth for key players in the robotics sector. Mitsubishi Electric stands at the forefront of this revolution, experiencing profits fueled by the increasing demand for factory robots across Asia. Discover how Mitsubishi’s strategic positioning and innovative solutions are capitalizing on the region’s push for enhanced efficiency and productivity. This article explores the factors behind this profit boom and its implications for the future of manufacturing.

Surge in Demand for Factory Robots Across Asia

Factory Robots Driving Factors Behind the Automation Boom

- The Asian manufacturing sector is experiencing an unprecedented surge in demand for factory robots. All driven by a perfect storm of economic and technological factors. Labor shortages, rising wages, and the need for increased productivity compel companies to embrace automation rapidly. This shift is obvious in industrial powerhouses like China and Japan, where manufacturers are aggressively integrating advanced robotic systems to optimize their production lines.

Key Industries Leading the Charge

- While the adoption of factory robots is widespread, certain industries are at the forefront of this automation revolution. Automotive manufacturing, electronics production, and food processing sectors invest heavily in robotic solutions to streamline operations and maintain competitive edges. These industries leverage robots to carry out tasks. These tasks range from precision assembly to quality control, resulting in significant improvements in efficiency and output quality.

Impact on the Asian Manufacturing Landscape

- The proliferation of factory robots reshapes the Asian manufacturing landscape. Further ushering in an era of “smart factories” and industrial digitization. This transformation not only enhances productivity but also elevates the skill requirements of the workforce. As companies integrate more sophisticated automation systems, there’s a growing demand for workers skilled in robot programming, maintenance, and oversight. This shift prompts a reevaluation of education and training programs to meet the evolving needs of the industry.

Mitsubishi Electric Sees Significant Profit Growth

Robust Performance in Industrial Automation

- Mitsubishi Electric’s latest financial report showcases impressive profit growth. All of which was primarily driven by the surging demand for factory automation systems in Asia. The company’s industrial automation division emerges as a key contributor to this success. Furthermore, factory robots take center stage in boosting revenue. This remarkable performance underscores Mitsubishi Electric’s strong position in the rapidly evolving landscape of smart manufacturing.

Strategic Positioning in Key Markets

- China and Japan spearhead the adoption of advanced robotic systems, with manufacturers increasingly integrating these technologies to optimize production lines. Mitsubishi Electric has strategically positioned itself to capitalize on this trend, reinforcing its market leadership in the automation space. By offering cutting-edge solutions that address the pressing needs of efficiency enhancement and labor shortage mitigation, the company has successfully tapped into the growing appetite for industrial robotics across the region.

Future Growth Prospects of Factory Robots

- As Asia continues to push for more advanced manufacturing capabilities, Mitsubishi Electric is ready for sustained growth. The company’s advancements in automation technology are set to play a pivotal role in shaping the future of industrial production. This boom in factory automation not only signals a transformative moment for Mitsubishi Electric but also reflects broader global trends toward smart factories and industrial digitization, positioning the company at the forefront of a technological revolution in manufacturing.

Factory Robots and Automation Playing Central Role in Revenue Boost

Driving Forces Behind Mitsubishi Electric’s Growth

- Mitsubishi Electric’s recent financial success is also largely attributed to the surging demand for factory automation systems across Asia. As industries in the region increasingly turn to advanced technologies to boost efficiency and address labor shortages, Mitsubishi’s robot and automation solutions further become indispensable tools for manufacturers looking to stay competitive in a rapidly evolving market.

China and Japan Lead the Charge

- At the forefront of this industrial revolution are China and Japan, where manufacturers are aggressively integrating sophisticated robotic systems to optimize their production lines. Mitsubishi Electric has strategically positioned itself to meet this rising demand, solidifying its leadership in the automation space. The company’s industrial automation division has seen robust performance, with factory robots playing a pivotal role in driving revenue growth.

Future Prospects and Industry Implications with Factory Robots

As Asia continues to push for more advanced manufacturing capabilities, Mitsubishi Electric is poised for sustained growth. This trend reflects broader global movements towards smart factories and industrial digitization. The boom in factory automation signals a transformative moment not just for Mitsubishi Electric, but for the entire manufacturing landscape in Asia. As efficiency and innovation become critical competitive advantages, Mitsubishi’s advancements in automation technology also shape the future of industrial production, potentially revolutionizing how goods are manufactured across the continent.

Factory Robots: Strategic Positioning to Meet Rising Regional Demand

Expanding Presence in Key Markets with Mitsubishi Electric’s Factory Robots

- Mitsubishi Electric strategically strengthens its foothold in Asia’s burgeoning automation market. The company also focuses on China and Japan, two powerhouses driving the region’s industrial transformation. By establishing a robust network of production facilities and distribution channels, Mitsubishi Electric ensures a swift response to the escalating demand for factory robots and automation systems.

Tailoring Solutions to Regional Needs

- Understanding that each market has unique requirements, Mitsubishi Electric also customizes its offerings to address specific industrial challenges. In China, where labor costs are rising, the company is developing cost-effective automation solutions that promise rapid return on investment. Meanwhile, in Japan, where an aging workforce is a pressing concern, Mitsubishi Electric is innovating with collaborative robots designed to work alongside humans, enhancing productivity while addressing labor shortages.

Investing in Research and Development

- To maintain its competitive edge, Mitsubishi Electric is heavily investing in R&D. The company is pushing the boundaries of artificial intelligence and machine learning integration in its robotics systems. This forward-thinking approach not only meets current market demands but also anticipates future needs, positioning Mitsubishi Electric as a long-term leader in the industrial automation space.

Outlook: Sustained Growth Amid Industrial Digitization Trends

As Mitsubishi Electric rides the wave of surging demand for factory automation in Asia, the company’s future looks bright. The outlook for sustained growth is strongly tied to the ongoing trends of industrial digitization and the push for smart factories across the region.

Expanding Market Opportunities

- With China and Japan leading the charge in adopting advanced robotic systems, Mitsubishi Electric is well-positioned to capitalize on this expanding market. The company’s strategic focus on innovation in automation technology aligns perfectly with the growing need for efficient, digitized production lines. As more Asian manufacturers seek to enhance their competitiveness through technological upgrades, Mitsubishi Electric’s expertise in factory robots and automation solutions will likely see increased demand.

Challenges and Adaptations

While the outlook is predominantly positive, Mitsubishi Electric must navigate potential challenges such as:

Intensifying competition in the robotics sector

The rapidly evolving technological landscape

Varying rates of industrial digitization across different Asian markets

To maintain its growth trajectory, the company will need to continuously innovate and adapt its offerings to meet the diverse needs of manufacturers across the region.

Long-term Industry Impact

- The sustained growth of Mitsubishi Electric in this sector signals a broader shift towards automation in Asian manufacturing. This trend is likely to have far-reaching implications for industrial productivity, labor markets, and economic development throughout the region, cementing the company’s role as a key player in shaping the future of Asian industry.

Key Takeaways

As you’ve seen, Mitsubishi Electric’s success in the booming Asian factory automation market underscores a pivotal shift in manufacturing. The surge in demand for robotics and automation systems reflects a broader trend towards smarter, more efficient production methods. By capitalizing on this industrial evolution, Mitsubishi Electric has not only boosted its profits but also positioned itself as a key player in shaping the future of manufacturing. As Asia continues to lead the charge in adopting advanced automation technologies, you can expect to see further innovations and growth in this sector. The rise of factory robots isn’t just transforming Mitsubishi Electric’s bottom line—it’s revolutionizing the entire landscape of industrial production across the continent.

More Stories

Google Closes Loophole That Let Hackers Bruteforce Your Hidden Phone Number

Recently, Google took decisive action to close a significant vulnerability that could potentially expose users’ hidden phone numbers to malicious actors.

Minimal-Data Optimization for Search Agent Training in RAG Systems

In the fast-changing world of RAG systems, training search agents with minimal-data optimization is a key challenge.

Southern Cross NEXT Lights Up Pacific with Ultra‑Low‑Latency High‑Capacity Cable

The Southern Cross NEXT (SX NEXT) submarine cable emerges as a pivotal innovation, redefining digital landscapes across the Pacific. Officially operational since July 2022, this 15,857 km four-fiber-pair marvel links Los Angeles and Sydney, with crucial connections to Auckland, Fiji, Tokelau, and Kiribati.

Starlink and OneWeb Gear Up to Transform South Korea’s Telecom Terrain

South Korea is entering the low Earth orbit (LEO) satellite communications field with strong government support for SpaceX’s Starlink & Eutelsat OneWeb.

Apple Unlocks Its AI: Developers Get a Passport to On‑Device Intelligence

At WWDC 2025, Apple has unveiled a transformative shift in its approach to artificial intelligence, offering developers unprecedented access to its on-device AI models through the innovative Apple Intelligence framework.

Nomupay and SoftBank Forge Path to Seamless Cross-Border Payments in Asia

In today's world, seamless financial transactions are essential for global commerce. Nomupay and SoftBank are leading a major change in...